Find Answers To Your Straw Bale Construction Questions

Essential articles, how to guides, and stories from builds across the countryDive into step by step how to articles, code and permitting tips, materials sourcing, design strategies, and workshop updates. Whether you are dreaming, planning, or building, you will find practical answers and inspiration from the field.

Explore by Category

- Construction Details 42

- Natural Plastering 20

- Workshops 15

- Tips and Trade Secrets 13

- Tools and Materials 10

- Inspiration and Community 9

- Strawbale FAQs 9

- Design and Engineering 7

- Contracting and Consulting 6

- Foundations 6

- Framing 6

- Moisture Management 6

- Codes and Building Officials 5

- Costs 4

- Financing and Insurance 4

- Homesteading 4

- Repair and Maintenance 4

- Flooring 3

- Landscaping and Yard Art 3

- Load Bearing Construction 3

- Finish Work 2

- Performance and Testing 2

- Product and Book Reviews 2

- DIY & Owner Builder 1

- Electrical 1

- Fire 1

- How To Straw Bale Construction 1

- Timber Frame 1

- Utilities 1

- Videos 1

Looking for Straw bale homes for Sale? View Here.

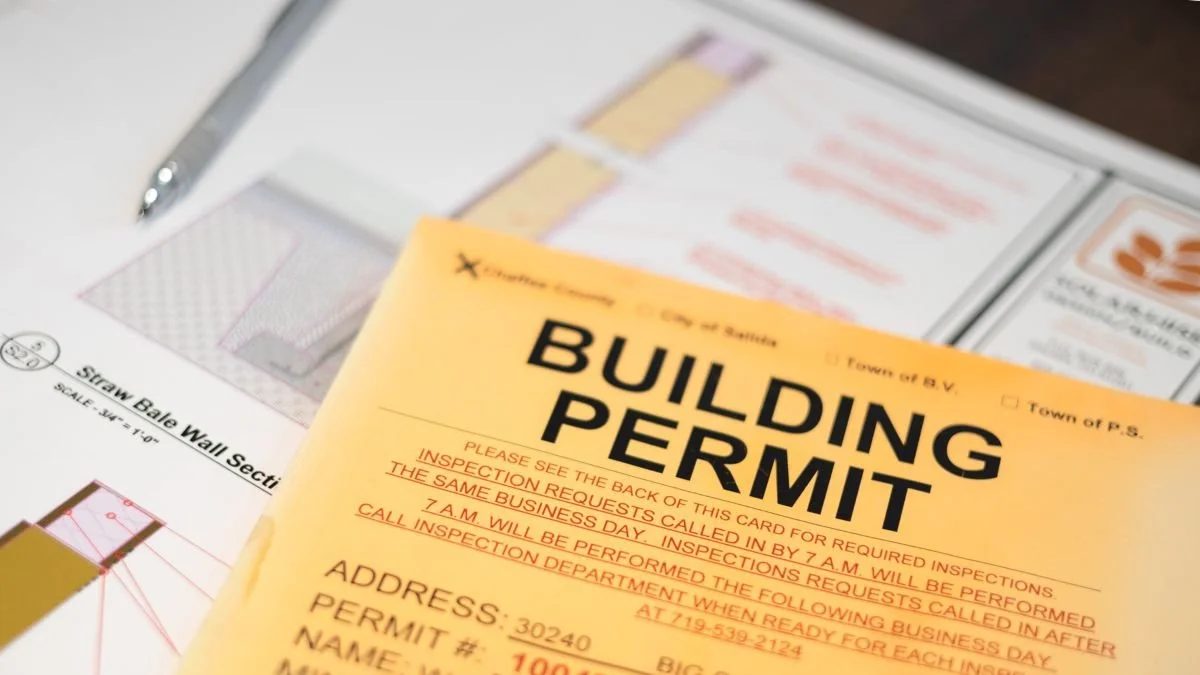

Building Permits for Straw Bale Houses

Keep these simple bullet points in mind when looking for building permit approvals for your straw bale house.

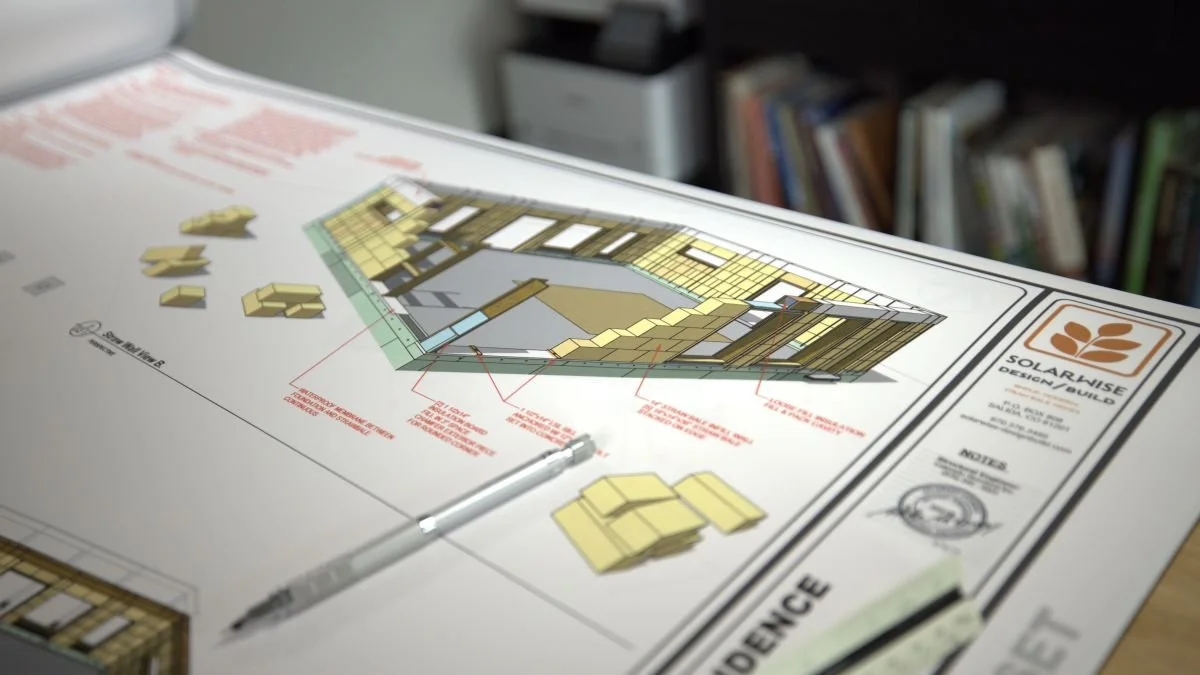

What to Figure Out Before You Break Ground on a Straw Bale Home

Planning a straw bale home starts earlier than most people expect. Learn which decisions to make before construction to avoid delays, rework, and cost surprises.

Financing a Straw Bale Home. What Lenders Look For and How to Prepare

Financing a straw bale home often stalls due to unfamiliarity, not performance. This article explains lender concerns and shows how preparation, language, and structure improve approval outcomes.

Hardwood Floors In A Straw Bale House

Straw bale homes work well with hardwood floors when you plan for floor movement and clean transitions at the walls. This post outlines why wood floors appeal to some straw bale homeowners, what expansion gaps do, and three reliable ways to finish the floor-to-wall connection.

Tool Organization Tips for a Smooth Straw Bale Build

Tool organization shapes how your job site runs. Clear homes for tools and a simple layout save time and keep work moving each day.

Why Building Paper Matters in Straw Bale Construction and Natural Plaster

Building paper protects wood, prevents plaster cracks, and supports a durable finish. This post explains why you use it and where to install it on a straw bale wall.

Community Spotlight: A Family’s Straw Bale Home Built from the Land

Discover how Jackie and Jim built a warm, quiet straw bale home from their own farm materials, a true labor of love and craftsmanship.

Building in Uncertain Times: Why Community Construction Still Works

As the world grows more uncertain, the choice to build your own home becomes an act of stability and connection. Drawing from years of straw bale workshops, I share why small, simple, and community-built homes remain the smartest path forward.

How NOT to Plaster a Straw Bale House - Avoiding Cold Joints

It is always best to limit the cold joints in your scratch coat as best you can. Here’s how you can avoid cold joints on your straw bale house walls and get the best result for your bale-protecting plaster job!

Why Plastic-Wrapped Bales Don’t Belong in a Strawbale Home

What about using plastic-wrapped bales in the construction of a strawbale home? Let’s have a deeper look at the pro/cons of this idea…

Plastering Straw Bale Houses in Cold Climates

Plastering straw bale houses in cold climates is a difficult process and site conditions have a big impact on the results. Learn more here.

What Still Makes Our Straw Bale Workshops Special

Our week long, hands on straw bale workshops still change lives. See how people, shared work, and simple joy make learning stick. Find a week that fits you.