What to Figure Out Before You Break Ground on a Straw Bale Home

Most problems with straw bale home construction do not start during construction. They begin during planning, when key decisions stay fuzzy or get postponed. Before equipment arrives or bales are ordered, a short set of questions deserves clear answers. Working through these early shapes how smoothly the rest of the straw bale construction process unfolds.

Clarify your goals before building a straw bale home

Start by naming your overarching priority and what success looks like. Is this a full time residence, a small retreat, or a phased build. Be honest about needs, time, and budget. Identify your nonnegotiables. Straw bale homes reward clarity. Vague goals often turn into mid build changes, which cost time and money.

Understand your building site and climate

Every site sets rules. Climate, access, slope, soils, and exposure all influence design choices. Spend time walking the land. Notice sun angles, wind, drainage, and winter conditions. These details guide wall systems, roof design, and moisture strategy long before drawings get finalized.

Know your straw bale construction code path

Straw bale construction fits many jurisdictions, but the approval path varies. Some areas accept prescriptive methods more readily. Others require engineering or alternative materials review. Identify the authority having jurisdiction early. Learn what documentation they expect. Visit the office, introduce yourself, and talk through what you plan to build. Starting relationships early reduces redesign and delays later.

Set a realistic budget early in the planning process

Early budgets work best when they reflect scope rather than wishful thinking. Account for materials, labor, equipment, engineering, permits, and contingencies. Straw bale walls often save on insulation but shift cost elsewhere, including increased labor. Knowing this early supports better trade-offs.

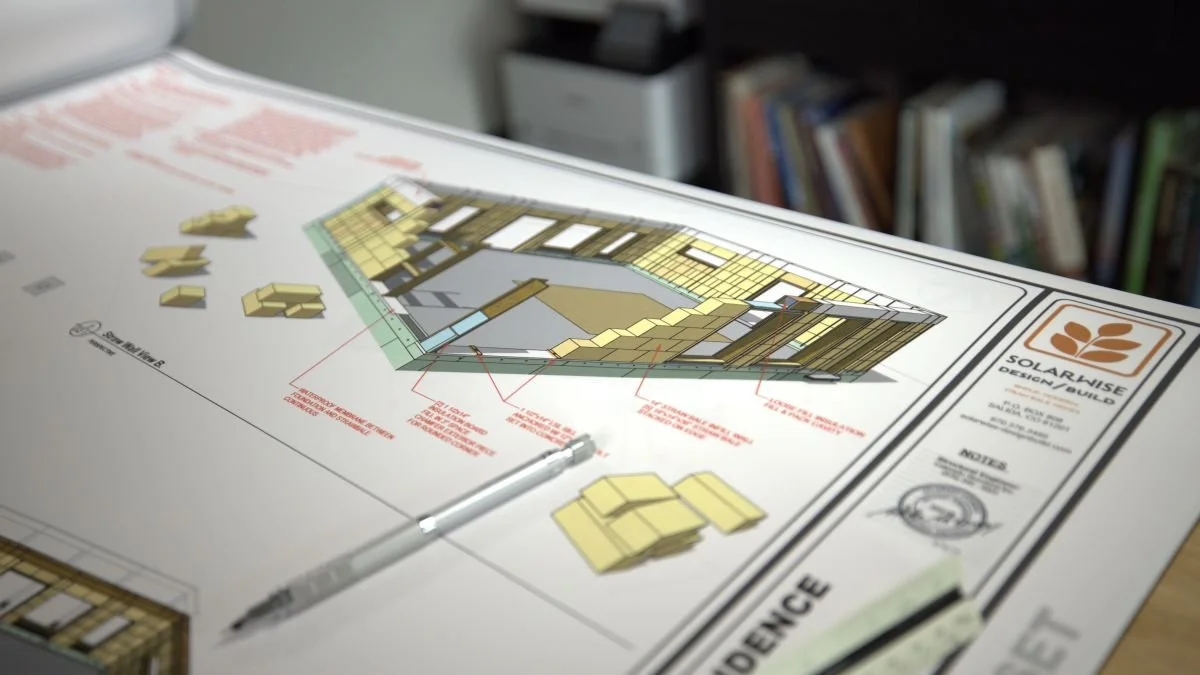

Choose your straw bale wall and roof strategy

Straw bale homes allow flexibility, but systems need coordination. Focus on infill wall systems paired with a clear structural approach, such as buck and box beam or timber frame. Factor in bale size, wall thickness, roof spans, and overhangs. These decisions affect structure, sequencing, and cost. Sorting them out early prevents conflicts during framing and plastering.

Plan construction sequencing early

Order matters. When walls go up, when plaster happens, and how the building gets dried in all influence the schedule. Exterior plaster timing often sits near the top of sequencing decisions. In many climates, exterior walls need to be plastered before temperatures drop below freezing. The exact cutoff varies by region, but this window drives earlier steps such as wall completion, roof protection, and material delivery. Working backward from plaster season helps align the entire build.

Decide what level of consulting support you want

Some self-builders want occasional guidance. Others benefit from ongoing input. Decide early whether you want consulting support, design development, or both. Matching support level to project complexity helps avoid gaps during critical moments.

Planning a straw bale home is real work

None of this looks like building, but all of it is. When these questions get attention before groundbreaking, the physical work tends to move with fewer corrections and less stress. Straw bale homes reward steady preparation.

If you want help applying these decisions to your own straw bale project, consulting offers project-specific guidance at the right moment. One-on-one sessions work well for early planning questions, site review, sequencing, and budget alignment.